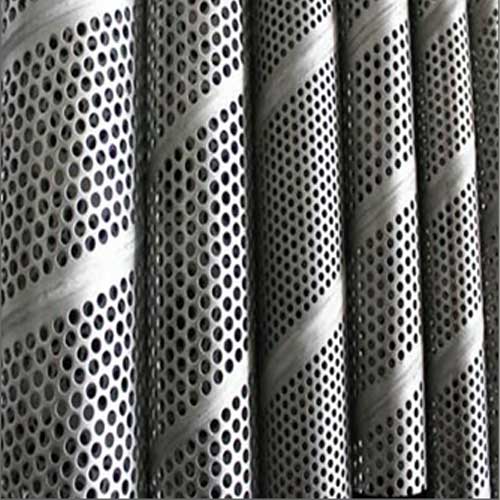

Perforated Ducting Mesh Manufacturers in Dubai

Hemant Engineering is a genuine and trustworthy Perforated Ducting Mesh manufacturers and suppliers in Dubai. With a strong commitment to excellence, we cater to industrial, commercial, and high-technology sectors by delivering products that meet international quality standards. Our Perforated Ducting Mesh is engineered for superior durability and enhanced airflow efficiency, ensuring long-lasting performance and reliability across diverse applications.

Types of Perforated Ducting Mesh

Being one of the best Perforated Ducting Mesh manufacturers in Dubai, we are offering high-quality Perforated Ducting Mesh such as:

- Stainless Steel Perforated Ducting Mesh – Due to its improved resistance to corrosion, this is used optimally where chemical and food processing industries are present. It has been hardened by the arrival of new nano-coating technologies and is also less in maintenance requirement. It is employed very extensively where cleanliness and rust are of the highest priority.

- Aluminium Perforated Ducting Mesh – Lightweight and high performance, aluminium mesh possesses excellent heat dissipation abilities. Surface resistance and strength are also supplied by special treatments like anodising. Increasingly being applied in HVAC units and advanced electronic cooling systems.

- Galvanized Perforated Ducting Mesh – The galvanized mesh is rustproof and waterproof since it has a permanent covering. Its life has been prolonged by the modern technology of galvanizing. It is utilised on a very big scale in industrial exhausts, ventilation, and exposed use.

- Custom Perforated Ducting Mesh – The unique hole shape and pattern design of custom designs gives the utmost air flow and filtering. CAD and CNC technology offers precise and equal production. Custom designs are used in complex HVAC systems and industrial filter systems.

Features of Perforated Ducting Mesh

We are one of the top Perforated Ducting Mesh manufacturers in Dubai, and our Perforated Ducting Mesh of all types is exported with new technology solutions like:

- Improved Airflow Efficiency – Our mesh protection is constructed of optimised hole geometry. Higher airflow distribution can be attained. Our design is based on new computational fluid dynamics (CFD) simulations. This attribute lies at the centre of HVAC and industrial ventilation use.

- Weather- and Chemical-Resistant – New materials science and coating technology are used to resist chemicals and extreme weathering. Numerous advanced surface treatments provide a much better service life. It is ideal for industrial and extreme marine environments.

- High Structural Strength – With better metals, our mesh resists high mechanical loading. Precision perforation is one of the advanced manufacturing processes that attain strength without adding excessive weight. It provides industrial and business performance.

- Design Options – One can get the mesh designed to accommodate all types of hole shapes, sizes, and patterns. Utilisation of the latest CNC and laser-cutting technology allows accuracy. This allows one to supply specialised applications such as laboratory ventilation systems and cleanrooms.

Advantages of Perforated Ducting Mesh

These types of new Perforated Ducting Mesh offer various types of advantages such as:

- Improved Energy Efficiency – Proper airflow reduces energy consumed in ventilation systems. Highly sophisticated computational simulation achieves maximum efficiency with low resistance. Buildings and industries achieve green energy levels.

- Improved Life of Performance – Enhanced quality materials and high-quality surface coating achieve maximum mesh life. Sophisticated corrosion protection systems eliminate unnecessary wear and tear. This reduces cost of maintenance and achieves maximum efficiency.

- Versatility of Application – Best to apply in applications in HVAC, filtration, industrial exhaust, and electronic cooling. Highly versatile to easily integrate into existing systems.

- Improved Safety and Hygiene – The stainless and aluminium types are easy to clean and maintain. Tech-based coatings prevent the growth of microbes on sensitive applications. This is especially important in the food, pharmaceutical, and medical industries.

Applications of Perforated Ducting Mesh

As the top Perforated Ducting Mesh suppliers in Dubai, our entire Perforated Ducting Mesh is equipped with new and widely employed in the following applications such as:

- HVAC Systems – Used in air diffusers, ventilation ducts, and filters. High-tech perforation patterns ensure superior airflow. This improves indoor air quality and enhances the system's efficiency.

- Industrial Exhaust and Filtration – Suitable for factories, chemical plants, and workshops. Corrosive and high-temperature air is managed using sophisticated mesh geometries. Ensures clean and safe working environments.

- Electronic and Equipment Cooling – Applied in server rooms, control panels, and electronic enclosures. High flow rates and heat dissipation rates prevent overheating. New design formulas allow connectivity to smart temperature control systems.

- Decorative and Architectural Use – Applies to façades, partitions, and panels. The modern laser cutting designs make it possible to have functionality as well as looks. It finds application in design and industry.

Hemant Engineering is a prominent Perforated Ducting Mesh manufacturers and suppliers in Dubai. Our solutions are designed to keep up with the current industry, business, and technology needs, providing reliability, energy efficiency, and optimum performance. Partnering with Hemant Engineering is partnering with innovation, quality, and long-term service for all your perforated ducting needs. Contact us today for more information!